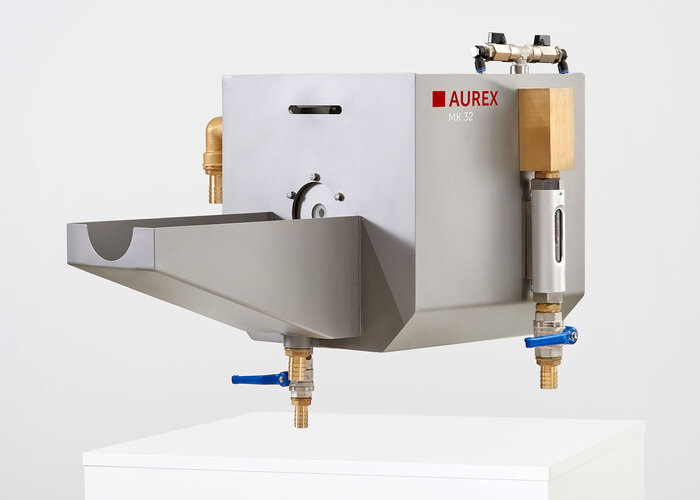

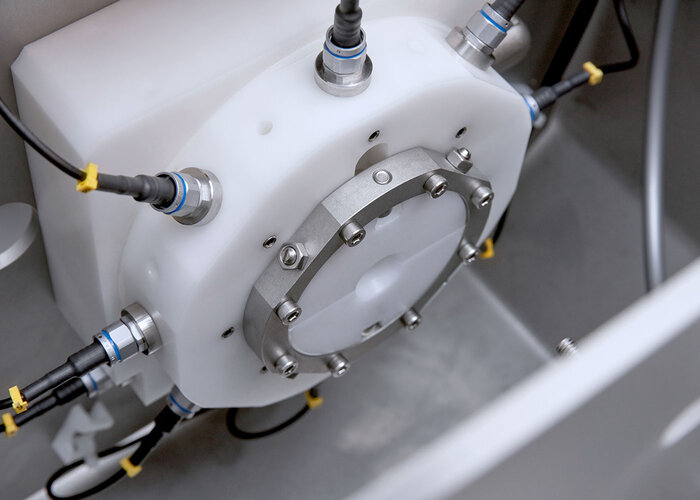

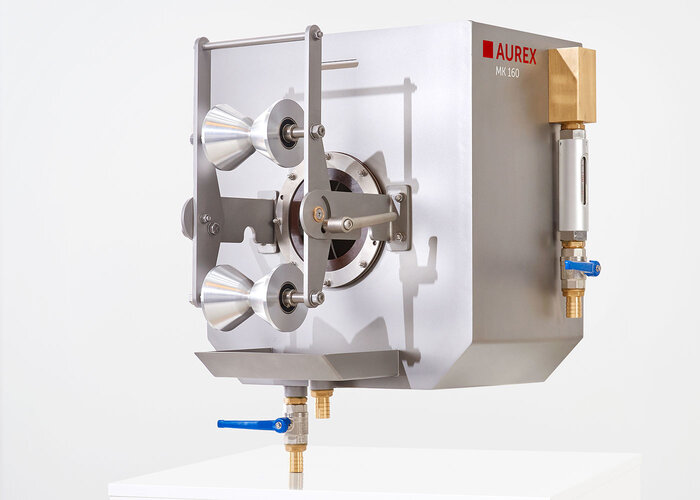

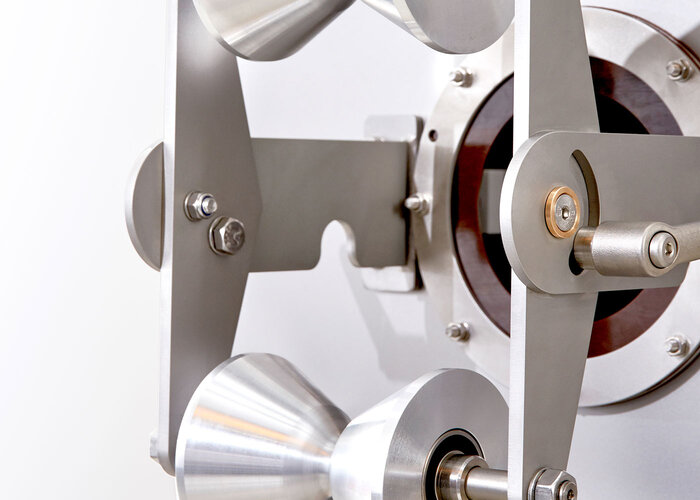

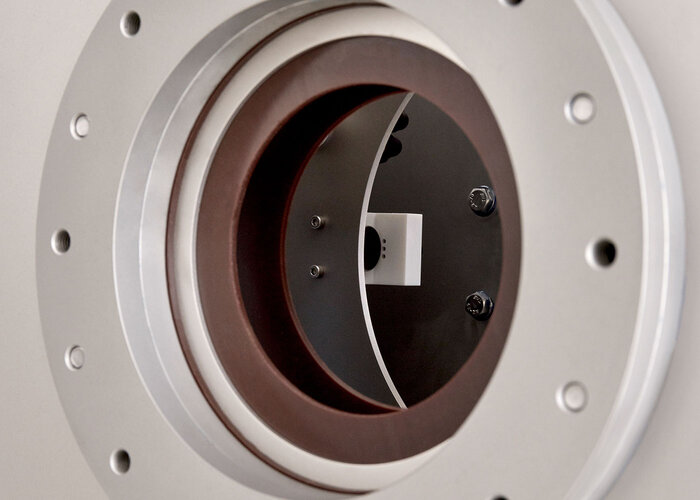

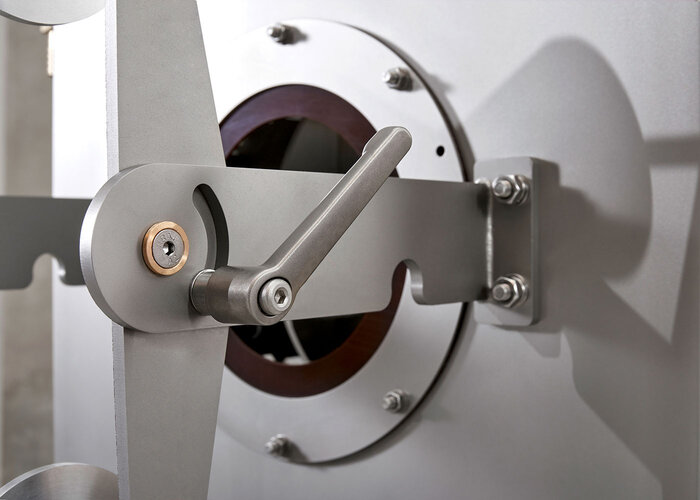

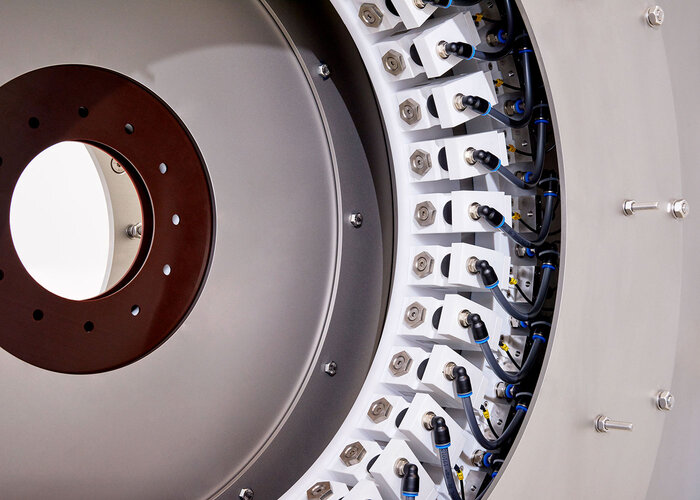

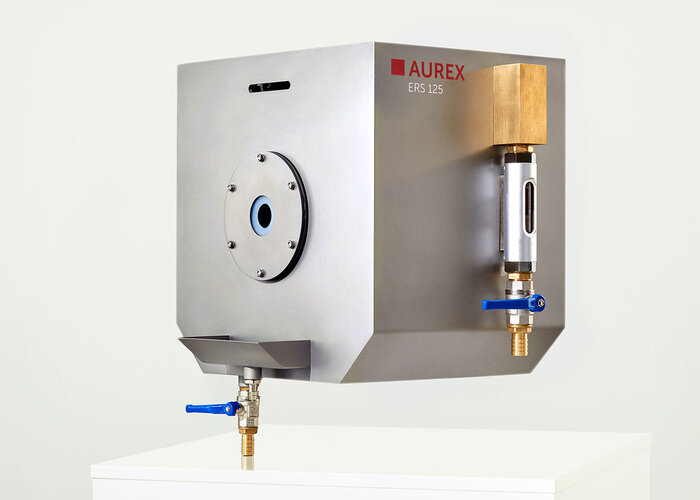

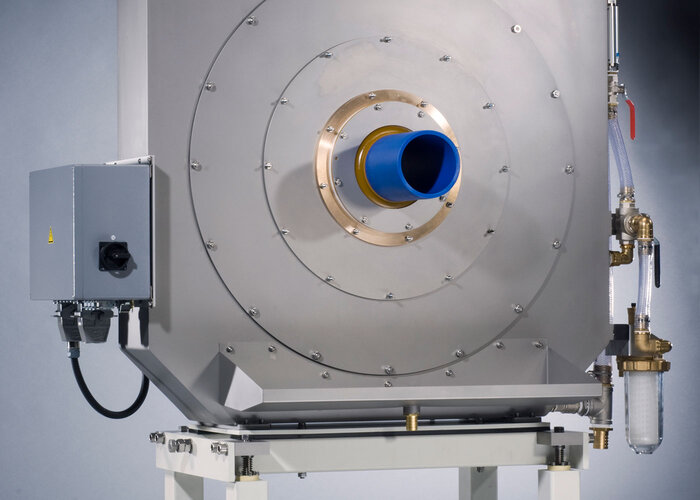

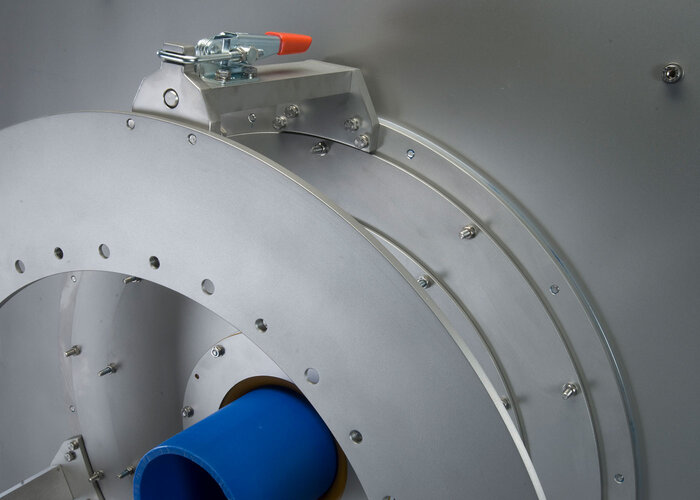

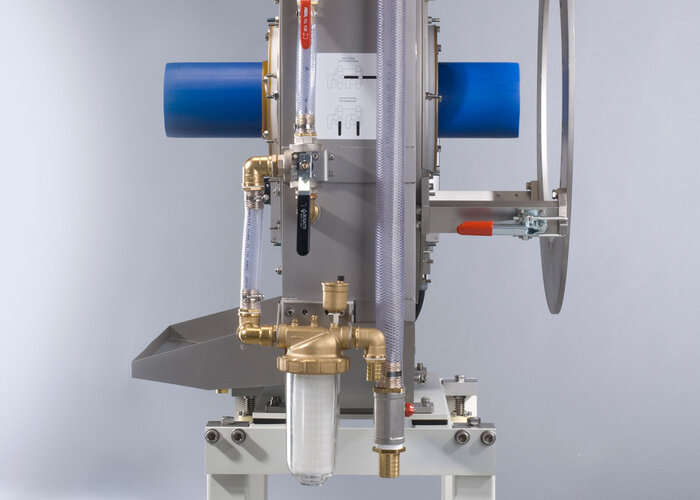

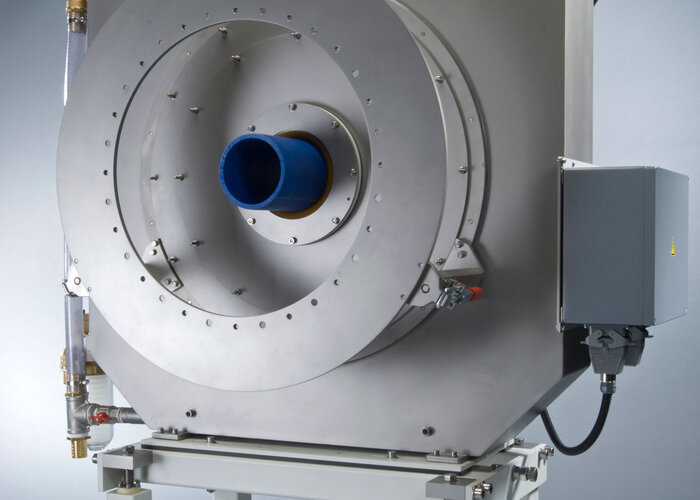

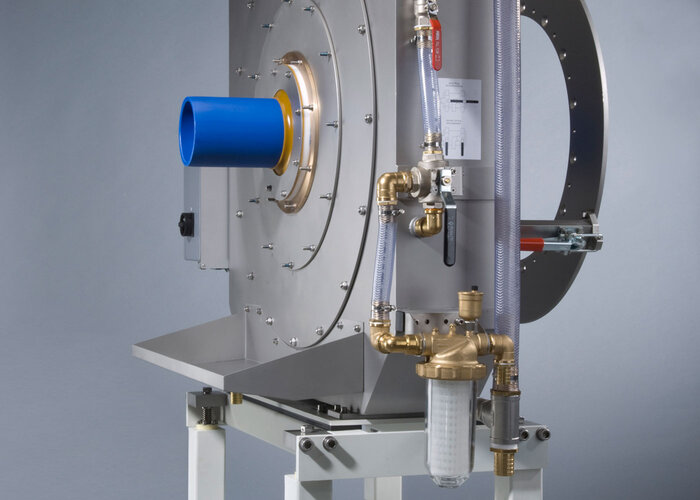

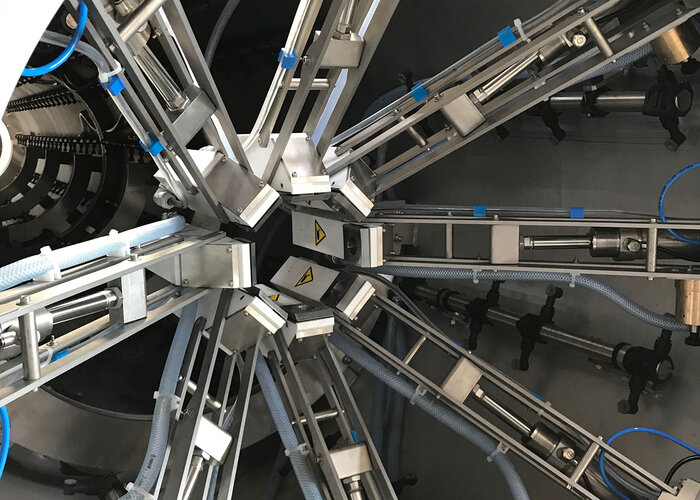

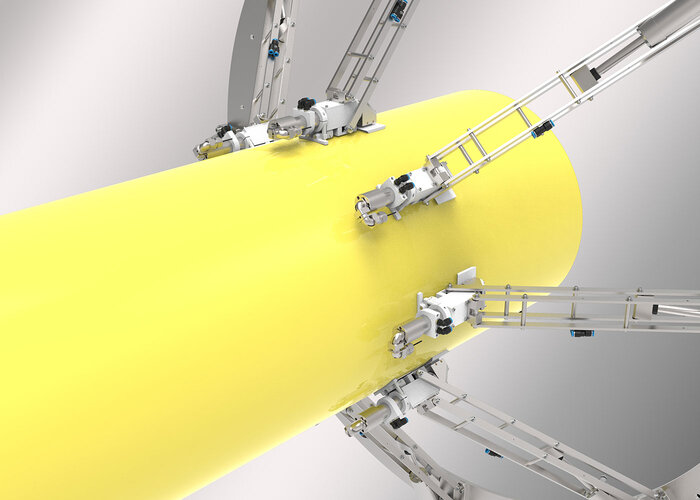

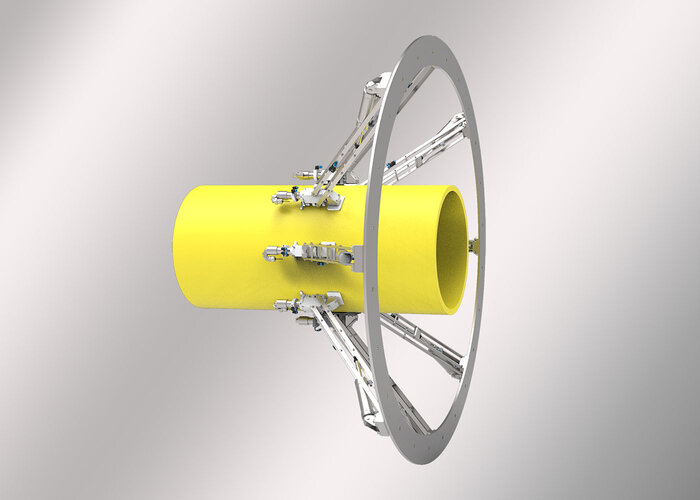

The AUREX AFM measuring chambers are flanged directly to the outlet of the vacuum tank. With up to 24 sensors a reliable and precise ultrasonic measurement with a centric pipe guidance is guaranteed. The measuring chambers are available for a diameter range of 63 - 630 mm. The AUREX AFM performs wall thickness and diameter measurement in parallel according to the number of sensors. The measurement data is documented for comprehensive quality verification. Since compliance with the tight tolerances for wall thickness, eccentricity, diameter and ovality is mandatory, detailed product information is available at any time.

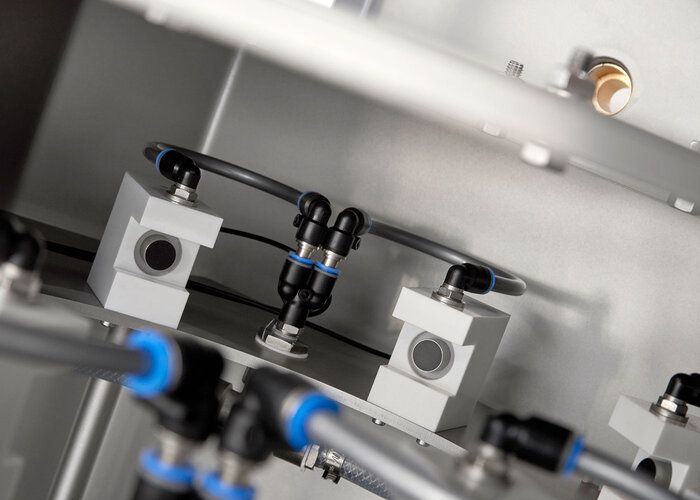

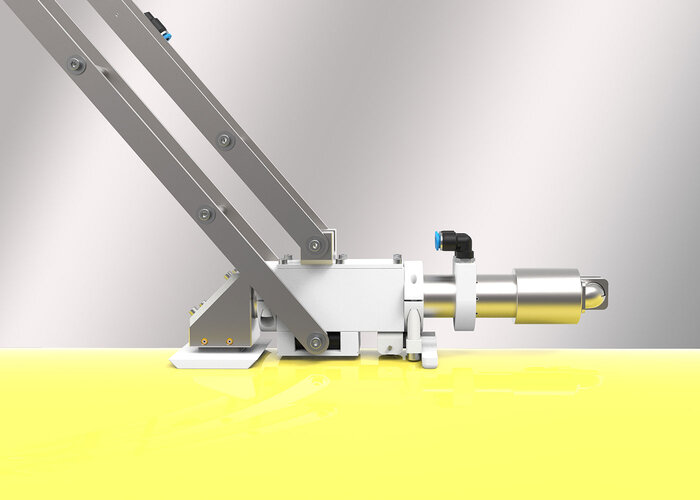

Optionally, the AUREX AFM can be equipped with the "Fast Specification Check MK/AFM", which enables a fast wall thickness check. Since the AUREX AFM does not completely cover the tube at the circumference, this wall thickness check can, for example, detect typical thin section rings, which are caused by jerks of the produced tube at the entire circumference.