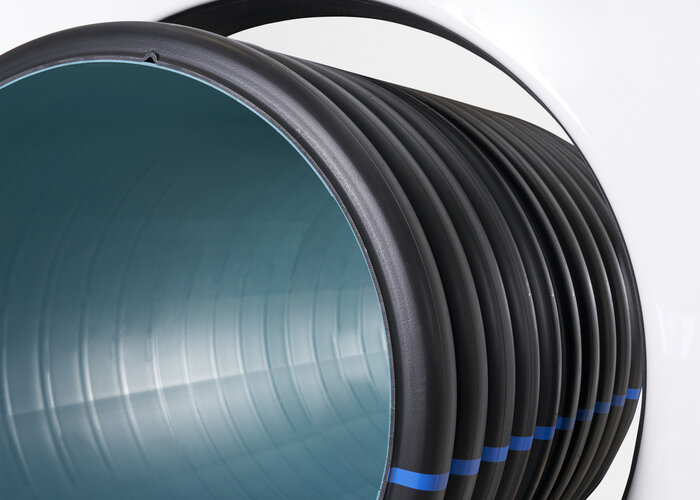

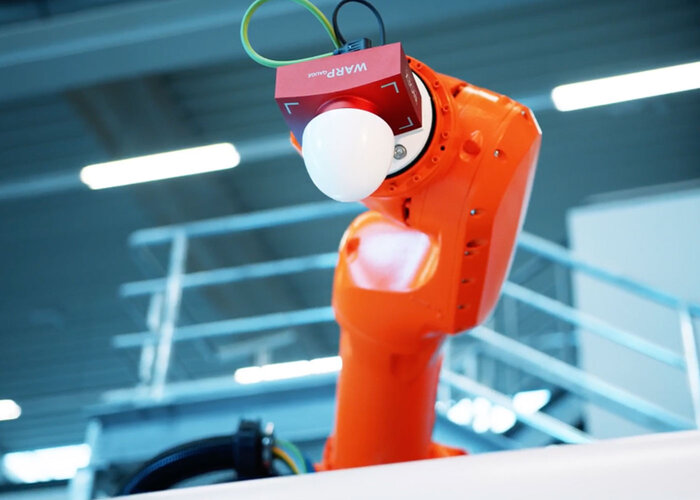

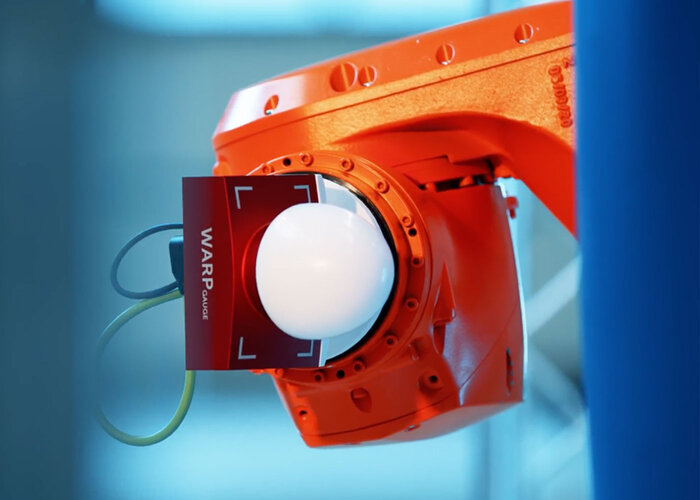

The WARP portable is a mobile, radar-based hand-held gauge for selective wall thickness measurement, specially designed for medium and large pipe extrusion as well as for sheets. The application possibilities are very flexible, whether as a quick centering aid in the start-up process, for final production control or as a stock control device. Not only wall thicknesses at pipe ends can be measured, but also the progression inside a pipe section or a sheet. The measurement itself is performed at the push of a button. The last 500 measured values including the measuring angle on the pipe as well as the time stamp are stored.

Over 400 WARP portable sold speak for themselves.

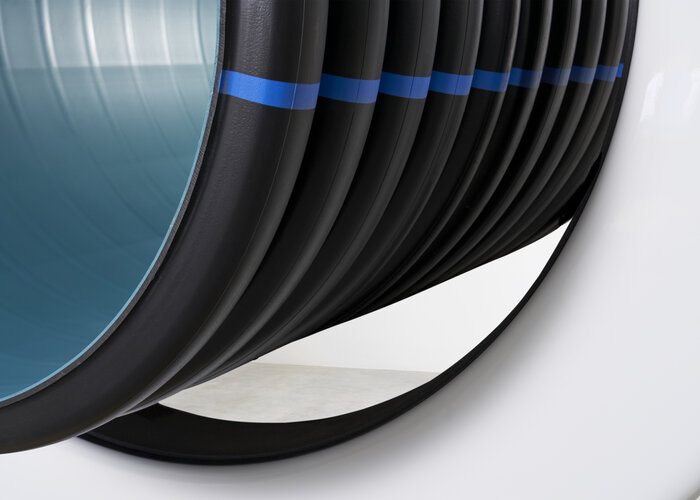

Proven technology now also for Industrial Packaging applications

Radar-based measuring technology has been established in pipe extrusion for years thanks to its precision and reliability. Due to its flexibility, it can cover a wide range of applications and is thus also suitable for numerous Industrial Packaging applications.

The iNOEX WARP portable offers a non-contact, non-destructive alternative to previous measuring technologies in the industrial packaging sector that either had to be carried out destructively or were complicated and time-consuming in terms of the measuring process.

WARP portable for industrial packaging applications

| Type | No. of sensors | Pipe dimensions (mm) | Reproducibility* (mm) | Accuracy (mm) | Measuring frequency (Hz) |

|---|

| WARP portable | 1 | 60 mm - any size | ±0,01 | ±0,03 (154 GHz Chip) ±0,05 (80 GHz Chip) | manually (max. 0,5 Hz) |

*Wall thickness measurement